In industrial environments, safety and stability are top priorities. Slippery surfaces can lead to accidents, injuries, and operational inefficiencies. Non-slip PP (polypropylene) sheets provide a reliable solution to this issue by offering excellent traction, durability, and resistance to various chemicals. These sheets are widely used in industries like manufacturing, warehousing, construction, and transportation to ensure a safer working environment.

Understanding Polypropylene Sheets

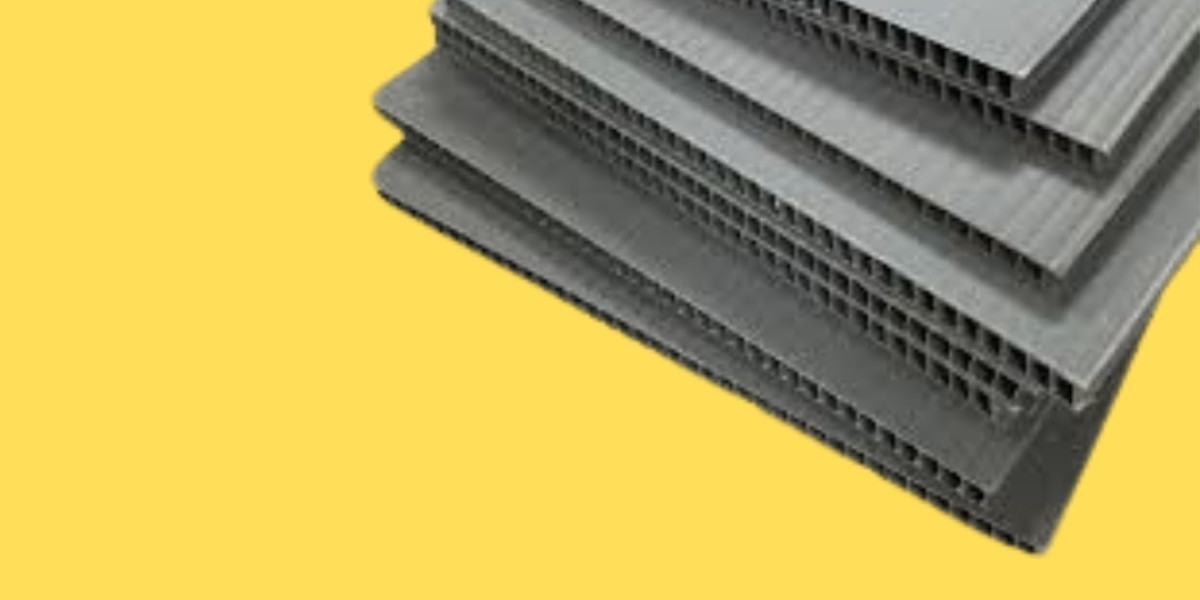

Polypropylene (PP) is a versatile thermoplastic known for its high strength-to-weight ratio, chemical resistance, and impact resistance. PP sheets are used for a variety of applications, including flooring, machinery support, and protective barriers. Non-slip PP sheets, in particular, have textured surfaces that enhance grip and prevent slips, making them ideal for industrial and commercial use.

Why Non-Slip PP Sheets Are Essential in Industrial Settings

Industrial facilities often have high foot traffic, heavy machinery, and exposure to oils, grease, and chemicals. These conditions make slip-resistant surfaces crucial. Non-slip PP sheets help reduce the risk of workplace accidents by providing a stable walking and working surface. Additionally, they are easy to clean, lightweight, and long-lasting, making them a cost-effective choice for businesses looking to improve workplace safety.

Key Benefits of Non-Slip PP Sheets

One of the primary advantages of using non-slip PP sheets is their exceptional durability. They can withstand heavy loads, extreme temperatures, and exposure to harsh chemicals without deteriorating. Additionally, these sheets are resistant to moisture and UV radiation, making them suitable for both indoor and outdoor use. Their anti-slip surface ensures that employees and machinery can operate safely, reducing downtime and increasing productivity.

Applications of Non-Slip PP Sheets in Industries

Non-slip PP sheets have a broad range of applications across various industries. In the construction sector, they are used for scaffolding and temporary flooring to provide stability. In manufacturing plants, they serve as protective barriers and flooring solutions for workers handling slippery materials. Warehouses and logistics centers use these sheets to create safer walkways and loading areas. Their versatility and strength make them indispensable in industrial settings.

Factors Influencing the Price of PP Sheet

The price of PP sheet depends on several factors, including raw material costs, production techniques, and demand in the market. The cost of polypropylene resin, a primary component in PP sheets, fluctuates based on global supply and demand trends. Additionally, specialized non-slip treatments and textured surfaces can add to the overall cost. Businesses looking for budget-friendly options should consider bulk purchasing or exploring different suppliers to get the best deals.

Polypropylene Price Trends and Market Fluctuations

The Polypropylene price is influenced by various economic and environmental factors. Crude oil prices, transportation costs, and production capacity all impact the overall cost of polypropylene products. In recent years, supply chain disruptions and increased demand for durable plastics have caused fluctuations in the polypropylene price. Companies must stay updated with market trends to make informed purchasing decisions and optimize their procurement strategies.

Comparing the Price for Polypropylene Sheets Among Suppliers

When sourcing non-slip PP sheets, it is essential to compare the Price for polypropylene sheets among different suppliers. Factors such as material quality, surface treatment, and customization options can affect the pricing. Some suppliers offer discounts on bulk orders, while others provide value-added services like precision cutting and custom embossing. Businesses should conduct thorough research and request quotes to ensure they get the best value for their investment.

Customization Options for Non-Slip PP Sheets

Many manufacturers offer customization options to meet specific industrial needs. Non-slip PP sheets can be tailored in terms of thickness, texture patterns, and color choices. Some companies also provide flame-retardant or electrostatic discharge (ESD) resistant variants for specialized applications. Customization allows businesses to enhance workplace safety while aligning with operational requirements.

Environmental Benefits of Polypropylene Sheets

Polypropylene is a recyclable material, making non-slip PP sheets an environmentally friendly option. Many industries are shifting towards sustainable materials to reduce their carbon footprint. Recycled PP sheets are now available, offering the same durability and performance as virgin PP sheets but with a lower environmental impact. By choosing eco-friendly PP sheets, companies can contribute to a more sustainable industrial ecosystem.

Installation and Maintenance of Non-Slip PP Sheets

Installing non-slip PP sheets is a straightforward process. They can be cut, shaped, and affixed using adhesives, screws, or interlocking mechanisms. Regular maintenance involves simple cleaning with mild detergents to remove dirt, grease, and debris. Unlike other flooring options, PP sheets do not require extensive maintenance, making them a hassle-free solution for industrial safety needs.

Cost-Effectiveness and Long-Term Savings

Despite the initial investment, non-slip PP sheets offer long-term cost savings. Their durability and low maintenance requirements reduce the need for frequent replacements, lowering overall operational costs. Additionally, improved workplace safety minimizes accident-related expenses such as medical bills, compensation claims, and productivity losses. Investing in quality PP sheets proves to be a smart financial decision for businesses.

Choosing the Right Supplier for Non-Slip PP Sheets

Selecting the right supplier is crucial to obtaining high-quality non-slip PP sheets at a competitive price. Factors to consider include product certifications, customer reviews, and the supplier’s reputation in the industry. Working with a reliable supplier ensures that businesses receive durable, high-performance PP sheets that meet safety standards and operational needs.

Future Trends in Non-Slip PP Sheets and Industrial Safety

As industrial safety regulations become more stringent, the demand for high-quality non-slip PP sheets is expected to rise. Innovations in polymer technology are leading to enhanced slip-resistant surfaces and improved material properties. Businesses like Pulkit Plastic Products should stay ahead of these trends to maintain compliance with safety standards and enhance workplace safety measures.

Conclusion

Non-slip PP sheets are an essential component in industrial safety solutions. Their durability, affordability, and anti-slip properties make them a preferred choice for various industries. Understanding factors like the polypropylene price, the Price of PP sheet, and the price for polypropylene allows businesses to make informed purchasing decisions. By investing in high-quality non-slip PP sheets, companies can create a safer, more stable work environment while ensuring long-term cost savings.

Frequently Asked questions (FAQs)

1. What are PP sheets?

PP sheets are flat, rigid, and versatile plastic sheets made from polypropylene, a thermoplastic polymer. These sheets are used in various industries for their durability, chemical resistance, and flexibility.

2. What are the advantages of using PP sheets?

- Durability: Resistant to wear and tear, making them long-lasting.

- Chemical Resistance: PP sheets can resist a wide range of chemicals, including acids, alkalis, and solvents.

- Lightweight: Easy to handle, transport, and install.

- Versatility: Available in a range of thicknesses, colors, and sizes for different applications.

- Environmentally Friendly: Polypropylene is recyclable, making PP sheets more eco-friendly than some other plastics.

- Waterproof: Resistant to water absorption and humidity, which makes them ideal for use in wet environments.

3. What are PP sheets used for?

PP sheets have a wide variety of applications across several industries:

- Packaging: Used for creating boxes, bins, and dividers.

- Signage: Used for outdoor signs, labels, and advertising boards.

- Automotive: Components like interior panels, bumpers, and car dashboards.

- Food Industry: Food containers, trays, and display cases due to their safety and chemical resistance.

- Industrial Applications: Used in chemical tanks, liners, trays, and protective coverings.

- Medical: Components for medical equipment, laboratory equipment, and cleanroom applications.