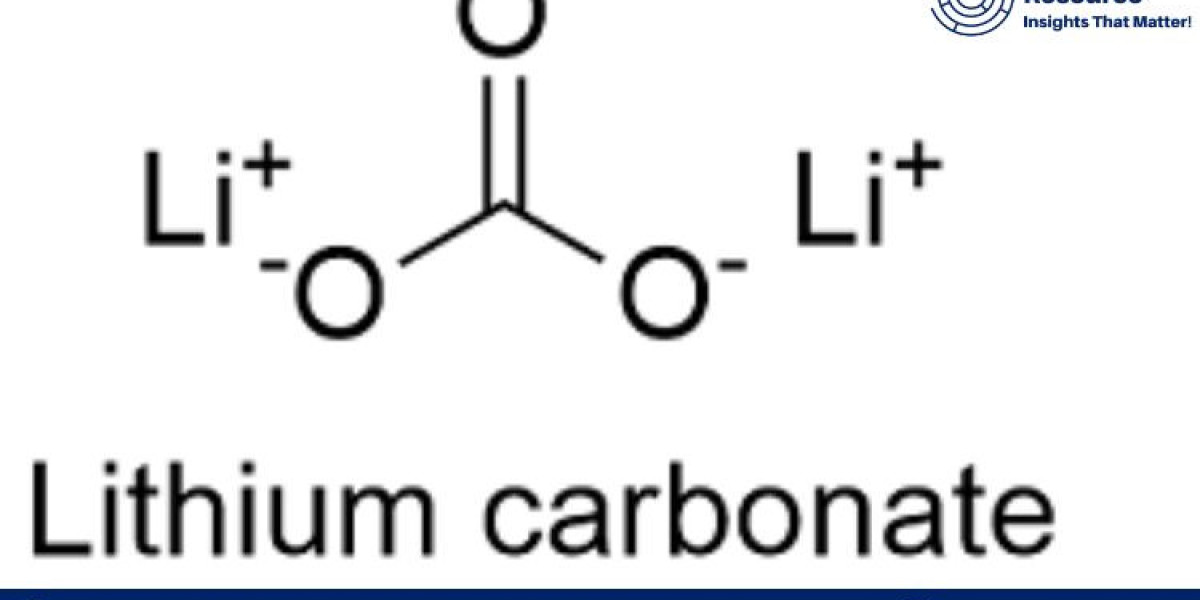

Lithium carbonate is a vital component in the production of rechargeable batteries, primarily used in electric vehicles (EVs), smartphones, laptops, and other portable electronic devices. As the demand for clean energy solutions rises globally, the importance of lithium carbonate has skyrocketed, particularly in the context of the growing electric vehicle market. Consequently, understanding the Lithium Carbonate Production Cost has become essential for manufacturers, investors, and stakeholders involved in the lithium supply chain. This article explores the key factors influencing the production cost of lithium carbonate, including cost models, industrial trends, labor charges, utilities, logistics, and supply chain considerations.

Understanding Lithium Carbonate Production Cost

The Lithium Carbonate Production Cost is impacted by multiple factors, from raw materials to energy consumption, technology, and labor charges. With the increasing global demand for lithium-ion batteries, particularly for electric vehicles, the production cost of lithium carbonate has been closely scrutinized by industry players.

Request a Free Sample - https://www.procurementresource.com/production-cost-report-store/lithium-carbonate/request-sample

1. Cost Model for Lithium Carbonate Production

The cost model for producing lithium carbonate involves a multi-step process that requires various raw materials, energy, and operational costs. Lithium carbonate is typically derived from two primary sources: lithium-rich brines and hard rock deposits. Both methods have unique cost structures, with brine extraction generally being cheaper than hard rock mining, though the latter may produce higher purity levels of lithium.

Raw Materials and Feedstock: The primary raw material for lithium carbonate production is lithium-containing compounds, which are sourced either from lithium brines (from salt lakes) or spodumene (a hard rock mineral). Both sources have different cost dynamics, with brines being more cost-efficient in terms of extraction, but hard rock mining offering higher concentrations of lithium. The cost of raw materials fluctuates based on mining operations, extraction methods, and market conditions.

Extraction Methods: The two major methods used to extract lithium are brine evaporation and hard rock mining. Brine evaporation involves pumping lithium-rich brines to the surface, where they are left to evaporate in large ponds before being processed into lithium carbonate. This process is more cost-effective but is limited by the availability of brine deposits. In contrast, hard rock mining, although costlier, involves extracting spodumene ore, which is then processed to produce lithium carbonate.

Energy Consumption: Producing lithium carbonate requires significant energy inputs, primarily for heating, evaporation, and chemical reactions during the processing stages. The energy cost plays a critical role in the overall production cost, and fluctuations in energy prices (especially electricity and natural gas) can have a direct impact on production costs.

2. Pre-feasibility Analysis for Lithium Carbonate Production

Before launching a lithium carbonate production facility, it is essential to perform a pre-feasibility analysis to assess the viability of the project. This analysis considers a variety of factors that influence the long-term profitability of lithium carbonate production.

Market Demand: Global demand for lithium is expected to rise significantly due to the growth of electric vehicles, renewable energy storage, and other applications requiring rechargeable batteries. A strong market demand ensures stable revenue for producers, but market fluctuations must also be considered in the pre-feasibility analysis.

Location and Site Selection: The location of the production facility can significantly influence the cost structure. Proximity to lithium reserves, energy sources, and infrastructure for transportation (ports, railways, etc.) can reduce transportation and logistics costs. Geographic location also impacts the availability of skilled labor and regulatory compliance costs.

Environmental Considerations: Lithium extraction, particularly from brine sources, can lead to environmental concerns, such as water depletion and pollution. Ensuring sustainable practices and adhering to environmental regulations are essential to avoid penalties and ensure long-term production feasibility.

3. Industrial Trends in Lithium Carbonate Production

Several industrial trends are shaping the production cost of lithium carbonate. As the demand for lithium increases, the cost structures of its production are also evolving. Key trends include:

Sustainability in Lithium Production: As sustainability becomes a growing concern, many lithium producers are investing in technologies that minimize environmental impact. Innovations in green lithium extraction technologies, such as direct lithium extraction (DLE), aim to reduce the environmental footprint of lithium mining and lower overall costs.

Technological Advancements: The development of more efficient extraction and refining technologies has the potential to lower production costs. Innovations such as closed-loop recycling systems for lithium and improved refining processes are helping to reduce the energy and raw material costs associated with lithium carbonate production.

Recycling and Circular Economy: As the demand for lithium increases, there is growing interest in recycling lithium from used batteries. Lithium-ion battery recycling can offer a secondary source of raw material for lithium carbonate production, potentially reducing the reliance on primary mining operations and contributing to lower production costs in the long term.

4. Labor Charges in Lithium Carbonate Production

Labor charges are an important aspect of the production cost for lithium carbonate. Given the complexity of the extraction and processing stages, skilled labor is essential to operate machinery, monitor quality control, and ensure safety in the production process. Labor costs can vary based on the location of the facility, with countries that have higher wage rates contributing to a higher overall production cost.

Skilled Workforce Requirements: Workers in lithium carbonate production must have specialized training in chemistry, engineering, and equipment operation. The cost of hiring skilled labor in regions with competitive labor markets can add significant overhead to the production process.

Safety and Compliance Costs: Lithium extraction and production can be hazardous, requiring extensive safety measures, equipment, and training programs. Compliance with safety regulations increases labor charges but ensures that production is carried out without accidents.

5. Utilities and Energy Costs in Lithium Carbonate Production

The energy and utilities required in lithium carbonate production are a significant portion of overall costs. As energy-intensive processes like heating and evaporation are involved, fluctuations in energy prices can dramatically affect production costs.

Electricity and Fuel Costs: Lithium carbonate production requires substantial electricity for the operation of pumps, compressors, and other equipment. Additionally, natural gas and other fuels are often used to provide the necessary heat for processing. Price volatility in energy markets can affect the overall production cost, particularly if energy prices spike unexpectedly.

Water Consumption: Water is a critical component of lithium extraction, especially in brine evaporation processes. The availability and cost of water resources can vary depending on the geographic location of the lithium extraction sites, adding an additional layer of complexity to cost calculations.

6. Logistics and Supply Chain in Lithium Carbonate Production

Logistics and supply chain management play a crucial role in determining the overall cost of lithium carbonate production. Once extracted and processed, lithium carbonate needs to be transported to various global markets, including electric vehicle manufacturers and battery producers.

Transportation Costs: Lithium carbonate is typically transported by rail, truck, or ship to global markets. The costs associated with transportation can vary significantly depending on the distance from the production facility to end-users, fuel costs, and the mode of transportation used. Efficient logistics systems can help minimize these costs.

Supply Chain Risks: Disruptions in the supply chain, whether caused by geopolitical factors, raw material shortages, or infrastructure issues, can lead to delays and increased costs. Establishing strong relationships with suppliers and logistics partners is essential for mitigating supply chain risks.

7. Request a Free Sample: Lithium Carbonate Production Cost Report

For an in-depth understanding of the Lithium Carbonate Production Cost, we offer an extensive report that covers cost models, pre-feasibility analysis, industrial trends, labor charges, energy costs, logistics, and supply chain insights. This report is an essential resource for anyone involved in the lithium supply chain, whether for investment, production, or procurement purposes.

For more detailed information or to request Free Sample - https://www.procurementresource.com/production-cost-report-store/lithium-carbonate/request-sample

By requesting a free sample, you gain access to detailed data and insights that can help you make informed decisions about your involvement in lithium carbonate production.

Procurement Resources for Lithium Carbonate Producers

Effective procurement practices are crucial for optimizing lithium carbonate production costs. Ensuring a steady supply of raw materials at competitive prices, securing efficient transportation networks, and managing energy use are critical components of a well-run procurement strategy.

Raw Material Sourcing: Building reliable relationships with suppliers of lithium brines or spodumene is vital for securing consistent access to high-quality materials at competitive prices.

Energy Management: Optimizing energy use in production processes, such as implementing energy-efficient technologies and exploring renewable energy options, can significantly reduce operating costs in the long term.

Logistics and Distribution: Establishing a robust logistics network to manage transportation and distribution is crucial for cost-effectively delivering lithium carbonate to end-users, especially in fast-growing markets like electric vehicle manufacturing.

Understanding the complexities of Lithium Carbonate Production Cost and implementing effective procurement strategies can enable producers to stay competitive and profitable as global demand for lithium continues to rise.

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA